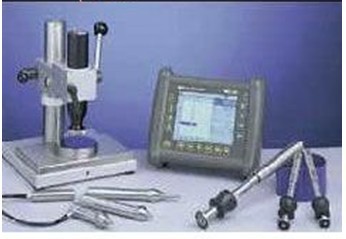

Product description:

MIC and sectional hardness tester will UCI method (ultrasonic contact impedance method) and rebound hardness test together as one. UCI method can be used to test the quality of a material with complicated shape fine materials, rebound method used to detect large coarse grain forgings and castings.

Product features

• combines CUI method (ASTM A1038) of quasi static hardness test and according to the rebound method (ASTM A956) dynamic hardness test of hardness meter

• UCI probe suitable hardness test for grain fine, with complicated shape or through the surface of the heat treatment

• rebound impact equipment is used for grain rough large element and forging and casting material

• test results in HV, HB, HRC, HRB, HS, the HL and N/best callus induction standard automatic conversion

, through the key and/or built-in touch screen operation, convenient alphanumeric data input

• power supply: the main network adapter (100 v - 240 v) or nimh batteries MIC twenty - BAT (internal charge)

• internal data record, and records to 5000 a series of measurements

According to different materials, test for rapid simple calibration. Calibration data can be stored and to tune out

• non-directional measurement without input any correction factor

• large color TFT screen, show all measurement related information, such as mean value, a single value or statistics

Clear, arrangement of data storage, can be simple and orderly storage measurement results. A series of measurements can be v and editing

use

• UCI test:

• assembly good mechanical equipment

• welding heat affected zone (such as: pipeline)

Heat treatment, surface (such as: tooth surface)

• coating (such as: gravure cylinder)

• rebound hardness test:

• steel or cast aluminum alloy mechanical parts or electric unit

Curly, texture, surface rough solid element

The production of the series, large parts

, heavy forging |

Whole house mineralized water system

Whole house mineralized water system